From here on, you will be linked to Nomura Co., Ltd. 's partner page. You can apply from the list of available positions at the link. (Please note that CIC may not always be recruiting.)

CIC NOTE

2025. 12-10

Takashi NaritaNice to meet you, I'm Narita, a CIC designer.

Recently, I bought a 3D printer at home and have become addicted to making things.

I feel that 3D printer technology has been developing rapidly over the past few years and is now being used in a variety of fields.

I have been involved in spatial design and production planning using various technologies, including 3D printers. I believe that there are shapes and productions that can be conceived by knowing the technology. In this article, I would like to introduce the 3D printer "G-code" that I have studied.

3D printers usually come with dedicated software to make them easy to use. You import a 3D model into this software, which then analyzes the 3D model and communicates it to the 3D printer to print it. G-code is the programming language that this software uses to tell the 3D printer how to operate.

Below is an example of G-code.

G92 E0

G1 F1500 X130 Y100 E3.5

G1 X130 Y130 E7.0

G1 X100 Y130 E10.5

G1 X100 Y100 E14.0

It's a string of characters like this, but roughly speaking, it's a command that says, "Print from this point to this point with this amount of filament at this speed."

With a regular 3D printer, the software automatically analyzes the 3D model, making it easy to produce highly accurate output. However, if you write G-code yourself, you can set the printer's movements from scratch. This allows you to control and output special shapes or shapes that the software struggles to create.

As an example, by writing G-Code directly, it is possible to output very thin shapes like the one below.

This repeats the command to output one ring on one layer and then move to the next layer.

The thickness is approximately 0.8mm due to the stacking of 0.4mm nozzles, and when used as a lampshade, it allows light to pass through.

This technique is also used in houses built using large 3D printers that print concrete.

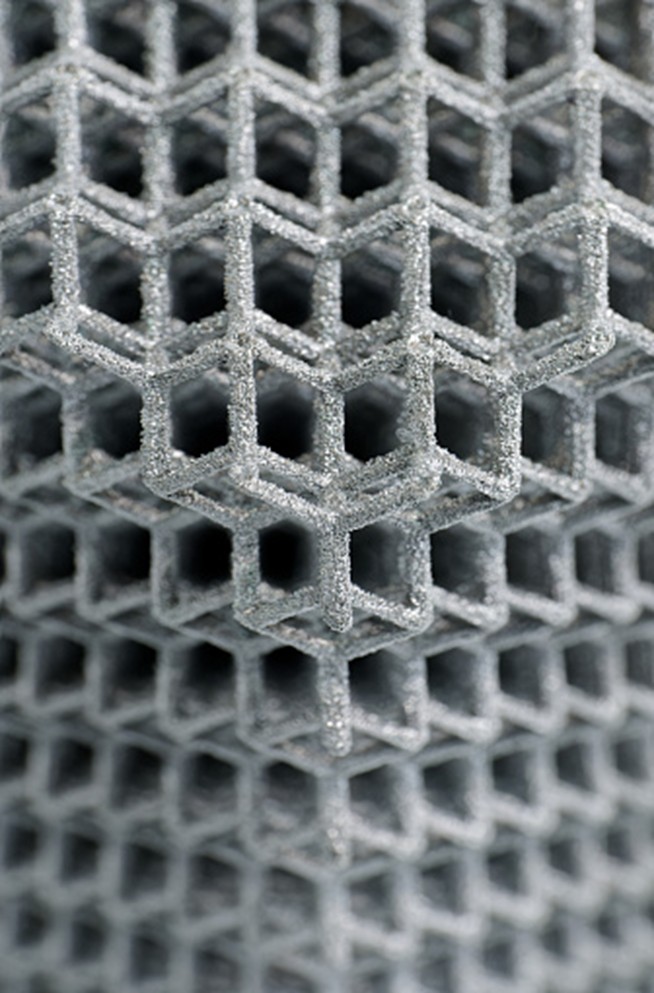

It is also possible to create wireframe-like shapes like the one in the following photo.

This is a method of printing where the 3D printer's output nozzle moves very slowly through the air, allowing the filament to cool and harden as it forms the shape.

(Photo is for illustrative purposes only)

This has become a bit technical, but I feel that by learning about technology in this way, there are many possibilities for new designs to be born.Technology is evolving at a dizzying pace, but I would like to continue my research and come up with new ideas.